In today's industrial landscape, the handling and stacking of high-strength panels across multiple industries face significant safety and efficiency challenges. For instance, in product manufacturing enterprises, the improper handling of panels can lead to a 30% increase in material damage rates, while in construction sites, inefficient handling processes can slow down project progress by up to 20%. These issues highlight the urgent need for a reliable solution.

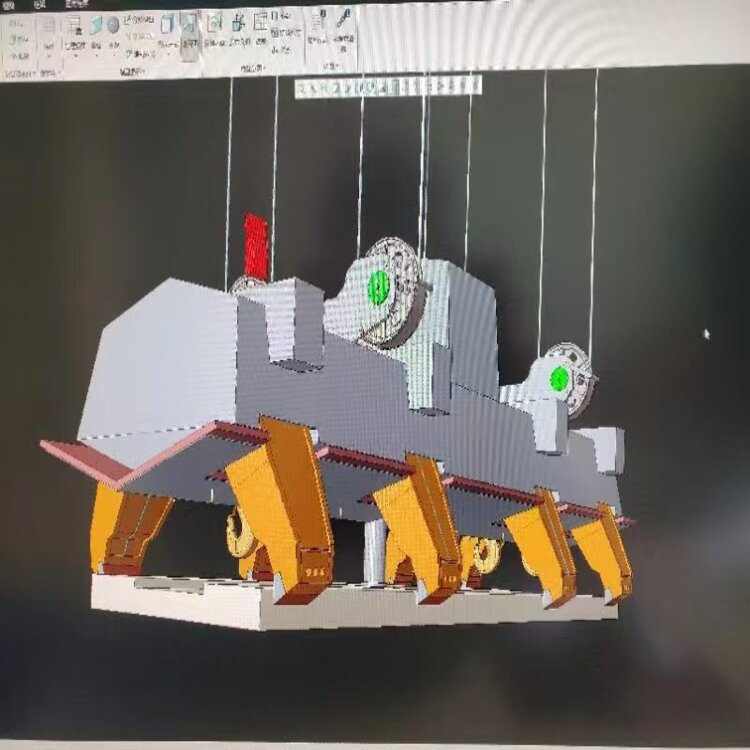

The high-strength panel handling and stacking tool is specifically designed to address these challenges, offering a safe and efficient way to move panels in various industries. Let's explore its features in detail.

The tool's safety design is one of its most remarkable features. It is constructed with high-quality, high-strength materials that can withstand heavy loads. For example, the steel used in its frame has a tensile strength of up to 800 MPa, ensuring long - term durability and stability. Additionally, it is equipped with a unique clamping and support system. This system uses precision - engineered clamps that can firmly grip the panels, reducing the risk of panel sliding and deformation during lifting. Tests have shown that this clamping system can reduce the panel sliding rate by over 90%, providing a high level of safety for operators.

This tool has a wide range of applications across different industries. In product enterprises, it can streamline the production process, reducing the time required for panel handling by up to 40%. In panel processing centers, it ensures the safety of materials during the transfer process, minimizing the loss of valuable materials. In仓储 and ports, it can handle large - scale panel shipments efficiently, increasing the throughput by 30%. And in construction sites, it can quickly move panels to the required locations, speeding up the construction progress.

Operating and maintaining this tool is a breeze. The operation process is straightforward, with clear instructions and user - friendly controls. Even inexperienced operators can quickly get the hang of it. Maintenance is also simple. Regular inspections of the clamping system, lubrication of moving parts, and checks on the structural integrity can ensure the tool's long - term performance. A well - maintained tool can have a service life of up to 10 years, providing a high return on investment for enterprises.

The tool offers multiple drive options, including mechanical, electric, pneumatic, and hydraulic. Each option has its own characteristics and is suitable for different operating environments. Mechanical drives are simple and reliable, suitable for small - scale operations. Electric drives are energy - efficient and quiet, ideal for indoor environments. Pneumatic drives are powerful and can work in harsh conditions. Hydraulic drives offer high - precision control and are suitable for heavy - duty applications. Enterprises can choose the most appropriate drive option according to their specific needs.

Many enterprises have already benefited from using this high - strength panel handling and stacking tool. A panel manufacturing company reported a 50% reduction in material damage and a 35% increase in production efficiency after implementing this tool. Another construction firm completed a project 25% ahead of schedule, thanks to the tool's efficient panel handling capabilities.

In conclusion, the high - strength panel handling and stacking tool is an ideal solution for ensuring production safety and efficiency. It can optimize enterprise processes, safeguard materials, and boost operational efficiency. By investing in this tool, enterprises can achieve sustainable business growth and gain a competitive edge in the market. Are you ready to take your panel handling operations to the next level? Contact us today to learn more about how this tool can transform your business!